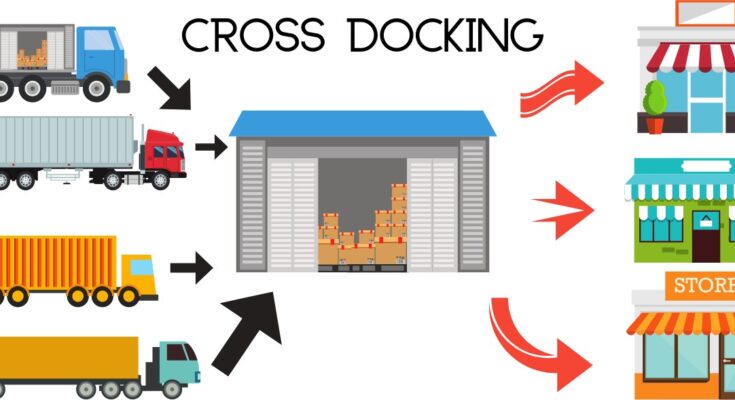

Cross-docking is the preferred method since it eliminates the need to temporarily store and collect goods before shipping. To combat the problem of inventory and storage costs, this is done. If you want your business to enjoy the benefits of Cross Docking in New York City, you need to understand what it is and how it works, and that’s exactly what we’ll accomplish in this piece.

What does it imply to cross-docking exactly?

Cross-docking is a kind of distribution in which goods are brought straight into a distribution centre or warehouse. Cross-docking is a term used to describe this configuration. The goods are not stored, but rather maintained in a “state of readiness,” where they are always prepared for shipment to stores. Harmony and rhythm must be woven throughout the process of receiving and distributing commodities. Cross-docking is a distribution cost-cutting strategy used by logistics firms.

When do we cross-docking, and what does it mean?

Warehouse operations include primarily four activities: receiving goods, storing them, collecting orders, and distributing them. The bulk of the expenses come from the two activities of order storage and order collection. Filling out a cross-docking form may drastically cut down on storage costs, and can cut down the time spent at the cross-dock preparing goods for distribution to customers to one day or less.

In the absence of items in the warehouse, cross-docking necessitates transporting the goods from the supplier to the warehouse rather than removing them from the warehouse for delivery. This is due to the fact that there will be no stock in the warehouse. However, due to the hazards associated with the longer lead time, cross-docking is only employed when an absolute on-time guarantee has been provided.

Typical examples of overlapping types

When it comes to warehouse management, cross-docking may take various forms. Any specific business will use the cross-docking method that works best with the way its products are sent.

In the industrial sector, cross-docking is becoming more common.

All purchased and arriving goods are to be received by the production plant throughout this process. Warehouse personnel may be responsible for accepting deliveries and initiating work on components for production orders.

A corporation, for instance, may rent storage space near its production facility and stock up on parts there before they’re needed. Since it is now able to predict the needs of each component thanks to the development of an MRP (production resource planning system), keeping a fixed stockpile is no longer essential.

Provider of cross-docking services

When the final product is ready to be sent to the client, it is combined with the incoming items from many suppliers into a mixed product palette. Computer component distributors, for instance, may order parts from a wide variety of manufacturers and consolidate them into a single order for the end user.

Conclusion

The logistics complex relies heavily on cross-docking; the 1.48-acre space set aside for this purpose is where a significant portion of orders are fulfilled. The usage of this strategy resulted in the delivery of eighty percent of the products to high-level business centres on the same day, with the remaining twenty percent being delivered the following day.